With the aim of safeguarding our planet, Master promotes initiatives to reduce environmental impact by acting directly on the company production processes and environmental policies, or indirectly by supporting and encouraging virtuous behaviour both inside and outside the company. Such commitment tends to improve the circular economy, CO2 emissions, sustainable mobility and environmental education, in the conviction that being a sustainable company means constantly improving as an organisation and above all facing every day with the firm commitment to safeguard the interests of coming generations (Bruntland report 1987).

In Master Group, we focus on environmental protection, prevention and control of pollution levels through practical actions to improve the efficiency of process water use and encourage separate collection and waste recycling management.

In accordance with the voluntary agreement signed with the Ministry of Environment and Energy Security, Master Group carried out the analysis and accounting of carbon footprint from the production of door and window accessories. The objective of the analysis is to quantitatively assess the amount of resources required and emissions produced to manufacture the various components of the lines produced by Master Italy Srl at the Conversano (BA) site.

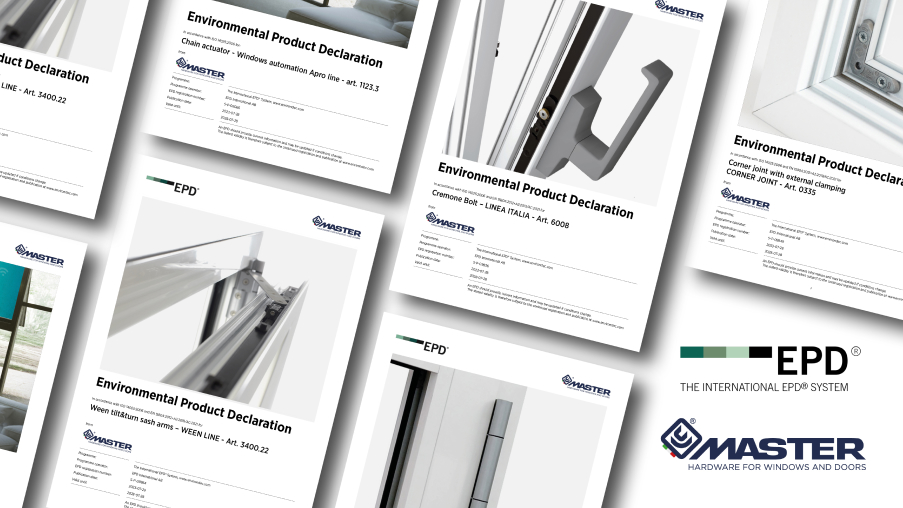

The project, initially undertaken only to calculate GWP100 (Global Warming Potential over 100 years), from this year onwards has been extended to other impact categories to obtain EPD (Environmental Product Declaration) certification according to The International EPD® System of the Program Operator EPD International AB.

The EPD reports are organised per product lines*:

The purpose of adopting this product certification and GWP100 calculation is to implement policies and strategies to reduce and possibly offset emissions by joining the international carbon credit market, in line with the commitment made by the Voluntary Agreement signed with the Ministry of Environment and Energy Security.

The interventions planned after the research aim to reduce the energy component through investments in new machinery, new photovoltaic systems, implementation of saving and process optimisation policies.

Research was conducted in compliance with the requirements of Standards UN EN ISO 14040:2006, UNI EN ISO 14044:2018 and UNI EN ISO 14025:2006. The functional unit of the research, consistent with the objective, is each code produced in a distinct manner (data per kg of product are also reported). For time limits, data will be considered on an annual basis and refer to the year 2022.

The geographical boundaries are global, while the production site is in Conversano (BA) Italy (cradle to grave analysis).

The software chosen for the development of this LCA analysis is SimaPro 9.5.

For processes involving the internal processing phases, plant-specific data was used, while for upstream processes questionnaires were provided to suppliers. Process data from the Ecoinvent 3.9 database are used.

The impact assessment method follows EN 15804:2012+A2:2019/AC:2021, and in particular GWP GHG follows the IPCC 2021 method of the Intergovernmental Panel on Climate Change, with a timeframe of 100 years.

The service life for doors and windows is 30 years, while it is 10 years for the automations line.

The decision to eliminate instruction manuals inside the boxes of many products (the transition from the paper version to digital version is taking place using QR codes), the reduction of printed matter and the use of FSC cards (made by responsible sources), the achievement of environmental certification 14001, are all responsible choices that meet the requirement to reduce the environmental impact of the company.

Leading companies are judged not only for the inherent quality of products and services they provide, but also for their sense of responsibility and the relationship they show to have with their surroundings and environment. The commitment we show today is aimed most of all to move us in this direction

Discover