Master Group has always focused on organisational, product and process innovation, aware that excellent growth results are always the result of attitude, dedication, skills and passion. Every year we allocate substantial investment to the development of an organisational system based on research, study and training, with an intense focus on sustainable staff development, the quality of materials and research into technologies for our products and processes.

PROCESS

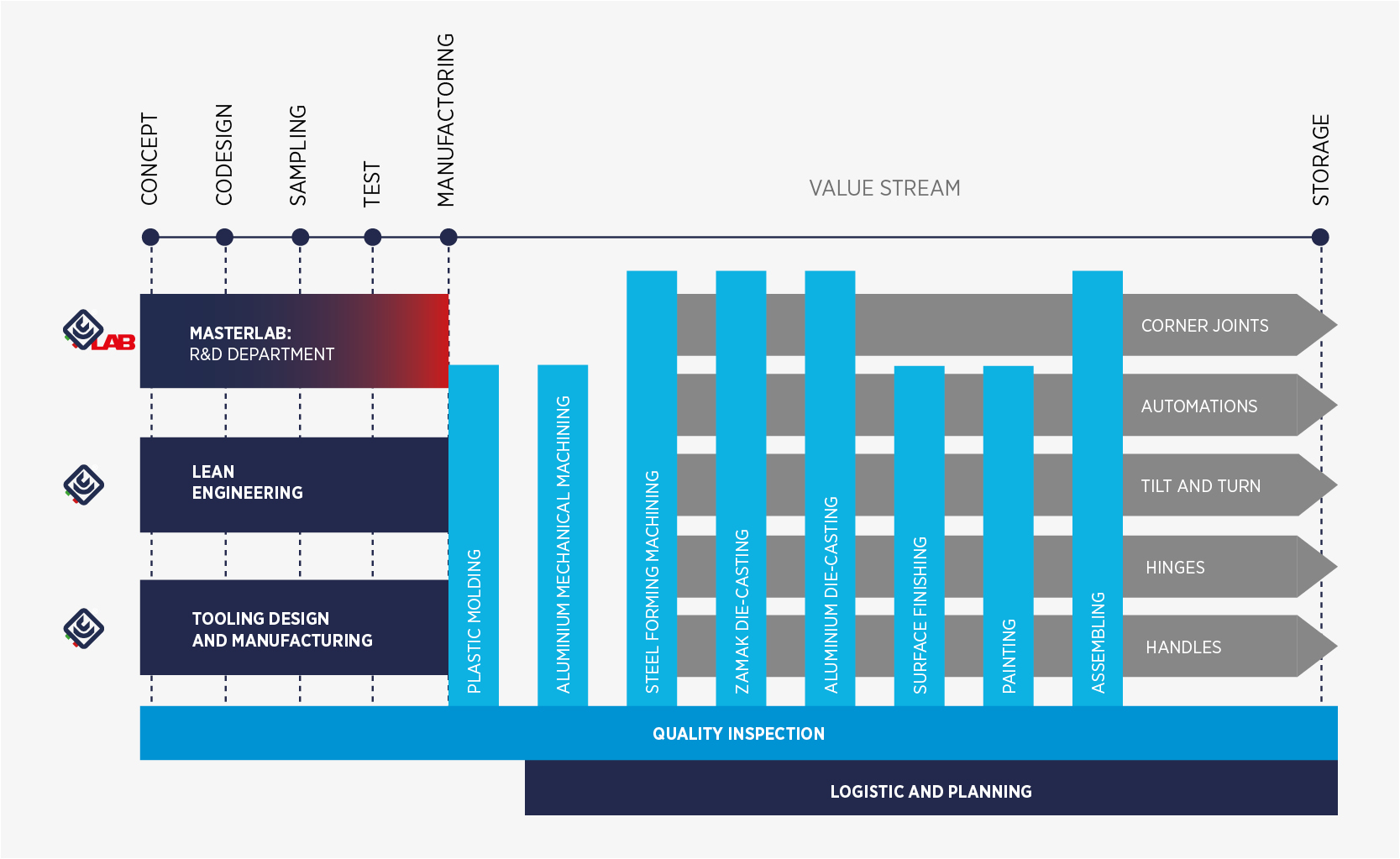

VALUE STREAM MAPProduction is managed according to the principles of Value Stream Mapping with reference to seven specific product lines: corner cleats, windows, handles, door, automations, sliding and curtain wall.

ORGANIZATIONAL

PEOPLEThe company is composed not only of machinery and processes but, above all, people linked by an organisation. Master considers the focus on human capital as one of the key aspects underlying its business.

PRODUCT

MASTERLABThe drive for innovation of the Master Group took shape in 2008 with the creation of MasterLAB, the Research & Development center with a testing laboratory.

In Master we take care of all phases of the production cycle in house, managing 94% of production to guarantee our customers utmost satisfaction. Strong production verticalisation allows us to manage the entire production cycle of an item in a single plant, starting from the processing of 5 raw materials: aluminium, zamak, steel, extruded aluminium and plastic. We follow a standard route divided into several stages. We start from the concept phase involving our MasterLAB R&D centre that gives shape to concepts and visions. Subsequent planning acts as a link between the concept and manufacture, with a joint effort to develop innovative solutions. Internal codesign facilitates a synergistic collaboration between production departments and offices such as lean engineering and tooling, aiming at the refinement of processes and the creation of highly efficient moulds. In the final phase, dedicated to mould creation, precision and attention to detail are essential. Lastly, the sampling phase of tests and controls in compliance with strict quality standards, which permeates the whole process from the start, allows development of a product with high standards of efficiency while guaranteeing maximum performance.

MasterLAB is Master’s Research and Development Center with a testing laboratory, and it is the core of the research in Master, who has been engaged since 2008 in innovation, changes in law about doors and windows and the much faster changes of the market.

MasterLAB is equipped with the most modern software and experimental tools, and methods, in order to perform research, study, design, experiments, and assistance.

Discover

The company is composed not only of machinery and processes but above all people linked by an organisation. We firmly believe in the centrality of people and teams in every change process involving the company. Our strength lies in the people who work every day with passion and commitment to ensure excellence and actively contribute to the Group’s success. We implement initiatives and events to improve the well-being of our employees and we are committed to ensuring sustainable development not only from an environmental point of view, but also social and economic, because we believe that without it there can be no progress.

Discover