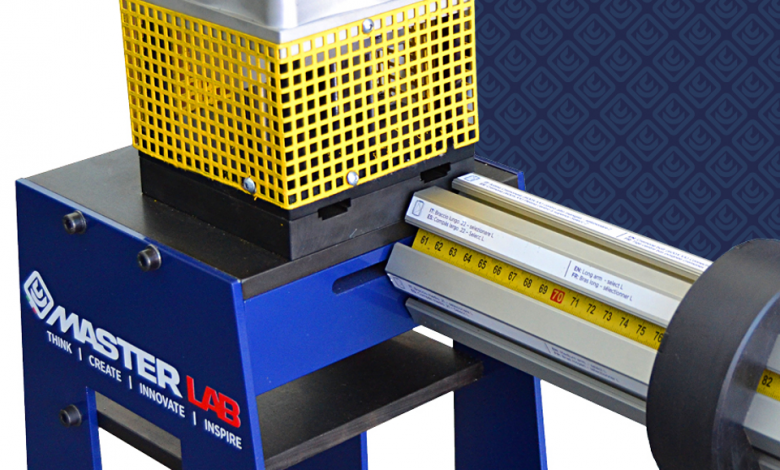

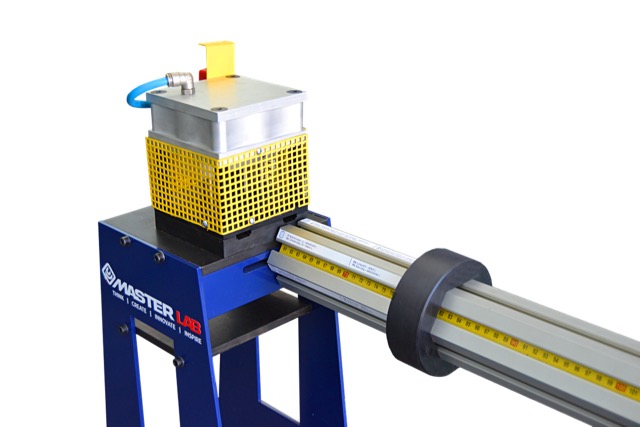

Master Group has always been committed to offering window and door fitters around the world smart solutions designed to facilitate and speed up the fitting of aluminium frames. With this in mind, the company has launched onto the market a new manual punching machine for cutting polyamide rods, making it possible to simply and intuitively carry out all necessary operations (hole, hole + cut, 3 holes + cut) for the preparation of Master Italy tilt and turn system rods.

With its innovative 6-position measurement beam, the new machine allows the cutting of tilt and turn rods by simply setting the width of the opening, its height and the position of the handle.

The instrument is an extremely useful aid for all frame fitters. It is versatile and universal, since it works indifferently with CE and R40 rods (only Master rod articles 2010.1 and 2010.2). Thanks to special jigs, the machine also allows the cutting of rods for all Master tilt and turn variants: with cremone bolt, handle or concealed hinge.

The punching machine comes in three versions: for the WEEN CE range (art. 2015.2), the WEEN R40 range (art. 2015.3) and the Tilt and Turn Sash 2.0 range (art. 2015.4). Each version is equipped with a specific measurement beam, though the metric booms for the other ranges can also be purchased separately.

The machine installation process is quick and easy and can be performed by a single operator (see video tutorial). The new manual punching machine, together with its automatic version (art. 2014), completes the Master Italy range of cutting machines offering fitters all solutions for the processing of tilt and turn systems.

Press release

Download